How Wooden Chess Sets Are Made: From Timber to Tournament Play

The Art and Craft of Making a Wooden Chess Set: From Timber to Tournament

Wooden chess sets have a unique magic about them. They’re not just tools for playing a game — they’re tactile works of art, shaped by skilled hands, steeped in tradition, and built to last for generations. Whether made from deep, lustrous ebony or the pale elegance of boxwood, a well-crafted wooden chess set is the very essence of chess itself.

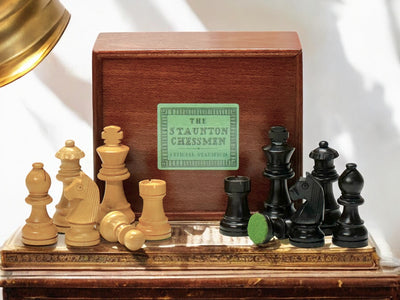

At The Official Staunton Chess Company, we’ve spent decades working with the world’s finest chess makers, producing everything from faithful Jaques reproduction chessmen to luxury Staunton tournament sets. We know that each piece of carved wood on your chessboard has a story — from the moment the timber is sourced to the final polish before it’s placed in your hands.

In this deep dive, we’ll explore the complete journey of a wooden chess set, revealing the craftsmanship, materials, and design choices that separate a good set from a great one.

1. Choosing the Right Wood: The Foundation of Quality

The first step in creating a quality wooden chess set is selecting the timber. The wood must be both aesthetically appealing and structurally reliable.

Common Premium Woods for Chess Pieces:

-

Ebony – Dense, deep black, and naturally luxurious, ebony has been the gold standard for dark chess pieces for centuries. It’s heavy, durable, and polishes beautifully, but its scarcity makes it expensive.

-

Boxwood – Pale, fine-grained, and capable of holding sharp detail, boxwood is the perfect counterpart to ebony for light pieces.

-

Padauk – A rich reddish-orange hardwood that darkens over time, adding warmth and vibrancy to a set.

-

Acacia – Affordable, sustainable, and naturally durable, acacia is increasingly popular as an alternative to traditional hardwoods.

-

Rosewood – Known for its swirling grains and reddish-brown tones, rosewood offers both strength and beauty.

For chessboards, walnut and maple are often chosen for their contrast and visual appeal. European makers also favour sycamore, while Italian boards may use mahogany or exotic veneers.

At The Official Staunton Chess Company, we ensure all woods are ethically sourced in compliance with international trade regulations such as CITES — protecting endangered species while maintaining exceptional quality.

2. Seasoning and Preparing the Timber

Raw timber must be carefully seasoned before it can be worked. If this stage is rushed or skipped, the wood may warp, crack, or shrink over time.

-

Air-drying – Large billets of wood are stored in well-ventilated areas for months, sometimes years.

-

Kiln-drying – Accelerates the process by using controlled heat and humidity.

-

Moisture testing – Ensures the wood’s water content is reduced to a stable level (often around 8–12%).

This patient preparation is vital — it’s what ensures your chess set stays straight and true for decades.

3. Turning the Pieces: Precision Meets Tradition

Once seasoned, the wood is cut into smaller billets — one for each chess piece. These are then lathe-turned to create the basic shapes:

-

Cylindrical stems for pawns.

-

Broader bases for stability.

-

Tapered necks leading to finials or heads.

Skilled turners work to precise measurements, especially for tournament-standard Staunton sets where FIDE dimensions must be met. Even the smallest deviation can affect the balance and uniformity of the set.

4. Carving the Knight: The Maker’s Signature

The knight is often considered the “signature” of a chess set. Unlike the other pieces, it can’t simply be turned on a lathe — it must be hand-carved.

This process involves:

-

Rough shaping the horse’s head.

-

Detailing the features — mane, ears, nostrils, and jawline.

-

Balancing symmetry across all four knights in the set.

In luxury sets, the knight may take several hours to complete, and different makers develop their own distinctive carving styles. In Jaques reproductions, for example, the knight’s arched neck and alert ears are hallmarks of authenticity.

5. Weighting for Playability

One of the most satisfying aspects of a quality chess set is the weight of each piece. Weighted chessmen feel stable, resist accidental tipping, and give a sense of authority in the hand.

To achieve this, a lead or steel weight is inserted into the base of each piece before the felt is applied. The size and placement of the weight are carefully adjusted so that the piece’s balance feels natural.

6. Adding the Felt: Protecting the Board

The base of each chess piece is fitted with a soft felt pad — traditionally green baize. This serves two purposes:

-

Protecting the board’s surface from scratches.

-

Allowing smooth movement of pieces during play.

In higher-end sets, the felt is hand-cut and perfectly aligned; in cheaper sets, it’s often glued on quickly, leading to peeling over time.

7. Finishing and Polishing: Bringing the Wood to Life

The final stage is where the chess pieces truly come alive:

-

Sanding – Multiple stages of sanding create a smooth, flawless surface.

-

Staining or ebonising – Some pieces are stained to mimic ebony or create rich colour contrast.

-

Polishing – Natural wax or oil is applied, often by hand, to protect the wood and enhance its natural grain.

Ebonising — a process where lighter woods like boxwood are dyed and polished to resemble ebony — allows for visually striking sets without the cost or scarcity issues of real ebony.

8. Crafting the Chessboard

A fine set deserves a fine board. Wooden chessboards are usually made by inlaying squares of contrasting woods — often walnut and maple — onto a stable plywood or MDF base to prevent warping.

Key considerations in a board’s construction:

-

Square size – Should match the king’s base (about 75% of square width).

-

Frame edging – Protects the inlaid squares and adds elegance.

-

Finish – Satin lacquer for durability, or natural wax for a softer sheen.

Italian boards, known for their high-gloss lacquer finishes, often double as decorative centrepieces.

9. Storage: Safeguarding the Investment

A well-made chess set can last generations, but only if stored correctly:

-

Slide-lid boxes – Traditional and compact.

-

Fitted cases – Provide individual slots for each piece.

-

Display cabinets – Show off luxury sets while protecting them from dust.

Mahogany is a popular choice for storage, matching the heritage feel of Staunton pieces.

10. Why Handmade Still Matters

Mass-produced sets can be functional, but they lack the subtle artistry of handcrafted pieces. Handmade chess sets:

-

Have individual character — no two pieces are identical.

-

Offer superior balance and handling.

-

Reflect centuries of tradition in their design and execution.

This is why, at The Official Staunton Chess Company, we continue to work with artisans who follow these time-honoured methods.

11. Matching Set to Player

Choosing a wooden chess set is as much about personality as it is about practicality:

-

For competitive players – Weighted Staunton pieces with a 3.75–4-inch king.

-

For collectors – Limited-edition reproductions with historical accuracy.

-

For display – Larger sets with ornate knights and luxury boards.

12. The Timeless Appeal of Wood

In an age where plastic and digital chess dominate, wooden chess sets remain the gold standard. They offer:

-

A tactile connection to the game.

-

Visual beauty that enhances any space.

-

Longevity — with care, they can be passed down for generations.

Final Thoughts

A fine wooden chess set is more than a collection of pieces — it’s the result of months, sometimes years, of patient craftsmanship. From selecting the right timber to carving the perfect knight, every stage adds to its beauty, balance, and heritage.

At The Official Staunton Chess Company, we are proud to uphold these traditions, ensuring that every set we offer meets the same standards of excellence that have defined the Staunton name for over 170 years.

Leave a comment